In between jobs we’ve been working on some new manifolds for our Capri Race car. Proper exhaust manifolds take a long time to make but there’s a lot of calculations to make before the welding begins. Race manifolds need to take into account all sorts of details about the design of the engine, head, valves, cams and even the gear ratio’s and rolling road power plot. Once all of that is taken into consideration the work can begin. You can see from the picture how much is involved with getting so much tube wrapped around the engine bay. The power gains are well worth it though.

Posts Tagged ‘mainfold’

Capri Exhaust manifolds

Friday, October 5th, 2012beef up your flange

Wednesday, May 25th, 2011This XR3i challenge car came to us in need of a custom engineering job. The front pipe to his race exhaust had been supplied by another well known exhaust builder but the front flange wasn’t strong enough. It kept bending causing it to blow. Also the centre section of the exhaust wasn’t properly supported causing it to droop down and catch kerbs during the race. We gas flowed the manifold as far as regulations allowed and had a new flange laser cut from industrial strength steel. We designed and built a new smooth flow front pipe and centre section, then mounted them all with extra hangers and supports.

Radical Improvements

Thursday, October 7th, 2010 Here’s a car that divides opinions, normally depending on whether you’re male or female. Most men seem to reckon it’s a thing of beauty, most women seem to disagree. One thing you couldn’t argue is it’s speed, these things are rapid. The formula is simple, take one super lightweight chassis, stick a motorbike engine in it and add a load of aerodynamics for grip. Radical really got it right with these cars and there success has been tremendous, including lap records and the Nurburgring circuit in Germany. This particular car has been having some difficulties with it’s exhaust. The header pipes on the exhaust manifold kick back around the engine and locate into collectors. The pipes keep coming loose and have cracked in several places so new sleeves have been added and the joints repaired. Less than a days work and the car is back on track frightening the locals, and probably the driver too.

Here’s a car that divides opinions, normally depending on whether you’re male or female. Most men seem to reckon it’s a thing of beauty, most women seem to disagree. One thing you couldn’t argue is it’s speed, these things are rapid. The formula is simple, take one super lightweight chassis, stick a motorbike engine in it and add a load of aerodynamics for grip. Radical really got it right with these cars and there success has been tremendous, including lap records and the Nurburgring circuit in Germany. This particular car has been having some difficulties with it’s exhaust. The header pipes on the exhaust manifold kick back around the engine and locate into collectors. The pipes keep coming loose and have cracked in several places so new sleeves have been added and the joints repaired. Less than a days work and the car is back on track frightening the locals, and probably the driver too.

Moggy 2000- nearing completion

Thursday, June 10th, 2010 The Morris minor having a zetec engine fitted is close to completion. Cooling systems, fuel system, exhaust, gearbox mounts, chassis mods to fit the starter and many other small jobs are all hugely time consuming but progress is slowly being made. There’s a few more small jobs then the car needs switching over to negative earth and the ECU needs fitting and programming. We can finally start looking forward to the maiden voyage!

The Morris minor having a zetec engine fitted is close to completion. Cooling systems, fuel system, exhaust, gearbox mounts, chassis mods to fit the starter and many other small jobs are all hugely time consuming but progress is slowly being made. There’s a few more small jobs then the car needs switching over to negative earth and the ECU needs fitting and programming. We can finally start looking forward to the maiden voyage!

No project too strange

Friday, March 12th, 2010This is one of those strange requests that instantly gets your attention. We received a contact from the website saying that a chap was fitting a Holbay engine into a commer van but needed an exhaust manifold making up. Sadly the engine arrived on a crate so we haven’t seen the finished project but from the description we’ve had it’ll be quite some creation. He wasn’t too concerned about tuned lengths, just getting everything fitted into the engine bay. It’s always hard without the car as we don’t really know how much space there is to play with but we marked everything out carfully and built it to a pattern so it should do the job nicely.

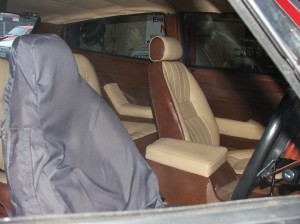

Cheap classic

Monday, January 25th, 2010It’s amazing that a car built in such relatively low numbers and with such striking styling should still be so cheap. The Scimitar was such a departure for Reliant and has carried it’s age well thanks to the fibreglass body. There may be nothing groundbreaking about the mechincals but thanks to some very strong parts being carfully borrowed from other manufacturers they are tough and pretty reliable as classics go. This car was bought for only a few hundred pounds but since then we’ve done some serious work done. Cosmetically it’s had a full respray, new carpets, the seats have been leathered and the headlining replaced to match. On the mechanical side of things it’s had a rare South African motorcraft 3.4L engine fitted. We’ve added some custom stainless exhaust manifolds and a full stainless system. It took 6 exhaust boxes in total to quieten everything down! It’s had lot’s of other bit’s a bobs like a dose of waxoyl and a full brake strip and reseal. Parts aren’t available for ars this age so everything had a clean up and new seals. In the end the master cylinder was modified to take one from a transit. I’m sure there wll be more improving to be done soon.