We’ve been doing a lot or Morris Minors recently. I think a lot of owners are pre-empting an increase in value so have taken to welding and waxoyling. This Morris needed lots of welding on the floor, but the further we got into it the more it needed. You can see from the pictures the amount of panels that went into the car, that’s not counting the ones we had to make! It took 2 solid weeks of cutting, dressing, welding, fabricating, welding again, dressing some more then waxoyling to get some strength back into the old girl. After all of that I’m sure she’ll be on the road for another 30 years yet.

We’ve been doing a lot or Morris Minors recently. I think a lot of owners are pre-empting an increase in value so have taken to welding and waxoyling. This Morris needed lots of welding on the floor, but the further we got into it the more it needed. You can see from the pictures the amount of panels that went into the car, that’s not counting the ones we had to make! It took 2 solid weeks of cutting, dressing, welding, fabricating, welding again, dressing some more then waxoyling to get some strength back into the old girl. After all of that I’m sure she’ll be on the road for another 30 years yet.

Posts Tagged ‘Waxoyling’

Moggy weldathon

Thursday, July 28th, 2011Crusty Moggy

Tuesday, June 14th, 2011This Moggy has been in to us before for a bit of rolling restoration. This time there was only a small crack in the chassis rail at the front. We cut it out and treated the inside of the rail with rust killer. A new chassis section was then grafted in and the whole thing treated to a dose of Waxoyl. The owner of this car takes a lot of pride in it. It’s a pleasure to take the time to do a thorough repair to a high standard.

When no-one else can help….

Thursday, June 10th, 2010

Ever seen a honda Jazz before? Not many people have because there’s not many around. Even rarer than Honda Jazz are parts for a Honda Jazz.

Most of these old jap cars have rotten away long before they reach the Retro Cool status that this little town car has achieved. It came to us for a little exhaust work and some of the inevitable welding that goes into owning an old car. To be fair it was in very good condition, just a patch or two here and there followed by a liberal dose of waxoyl. The main problem was the bottom ball joints in the front suspension. They are as rare as the preverbial teeth from a hen and when we did find some they cost more than the car did. The solution was to break out the parts catalogue and get welding.

We found that some Peugeot ball joints had the same dimensions so the lower arms were measured and moddified to take some bolt on ball joints. It takes a whole lot longer to do than it does to say but we’ve done this several times on track cars to get more camber on them and the results speak for themselves.

Cheap classic

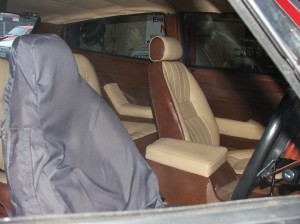

Monday, January 25th, 2010It’s amazing that a car built in such relatively low numbers and with such striking styling should still be so cheap. The Scimitar was such a departure for Reliant and has carried it’s age well thanks to the fibreglass body. There may be nothing groundbreaking about the mechincals but thanks to some very strong parts being carfully borrowed from other manufacturers they are tough and pretty reliable as classics go. This car was bought for only a few hundred pounds but since then we’ve done some serious work done. Cosmetically it’s had a full respray, new carpets, the seats have been leathered and the headlining replaced to match. On the mechanical side of things it’s had a rare South African motorcraft 3.4L engine fitted. We’ve added some custom stainless exhaust manifolds and a full stainless system. It took 6 exhaust boxes in total to quieten everything down! It’s had lot’s of other bit’s a bobs like a dose of waxoyl and a full brake strip and reseal. Parts aren’t available for ars this age so everything had a clean up and new seals. In the end the master cylinder was modified to take one from a transit. I’m sure there wll be more improving to be done soon.

Classic cool

Thursday, June 18th, 2009June 2009- An early 70’s Porsche 911 came in with starting problems. It had an old KKK mechanical fuel injection system on it so no point plugging the scanner in on this one! Turned out to have a small solenoid that literally dribbled fuel into the inlet manifold as you crank it over. We reconnected a broken wire and away it went. Stone age design and simplicity itself but it works.

Also in was a 60’s Mustang, proper old school american muscle. Just needed waxoyl and a few niggles sorting out. Nothing major but a lovely car and a perfect example at that.